Bottle Openers: Class 2 Levers Explained

Ever wondered about the clever engineering behind that handy tool you use to pop open your favorite beverages? You’re about to discover the fascinating world of levers hiding in plain sight. A bottle opener is a perfect example of a class 2 lever, a simple machine that makes our lives easier every day. In this article, we’ll dive deep into the mechanics of bottle openers, exploring why they’re classified as class 2 levers and how this classification contributes to their efficiency.

Whether you’re a curious mind, a science enthusiast, or simply someone who enjoys a cold drink, understanding the lever system behind bottle openers will give you a new appreciation for this everyday tool. Let’s uncap the secrets of bottle opener mechanics and explore the clever physics that makes opening bottles a breeze.

The Basics of Levers: A Refresher

Before we pop into the specifics of bottle openers, let’s crack open the basics of levers. These simple machines have been making our lives easier for thousands of years, and understanding them is key to appreciating the genius of bottle opener design.

What Exactly Is a Lever?

A lever is a simple machine consisting of a rigid object, usually a bar or beam, used to lift weights or overcome resistance. It works by balancing forces around a fixed point called the fulcrum. When you apply force to one end of the lever, it creates a mechanical advantage that amplifies the force at the other end.

Levers are all around us, from seesaws in playgrounds to tweezers in your bathroom. They’re so common that we often use them without even realizing it. And yes, that bottle opener in your drawer? It’s a lever too!

The Three Classes of Levers Explained

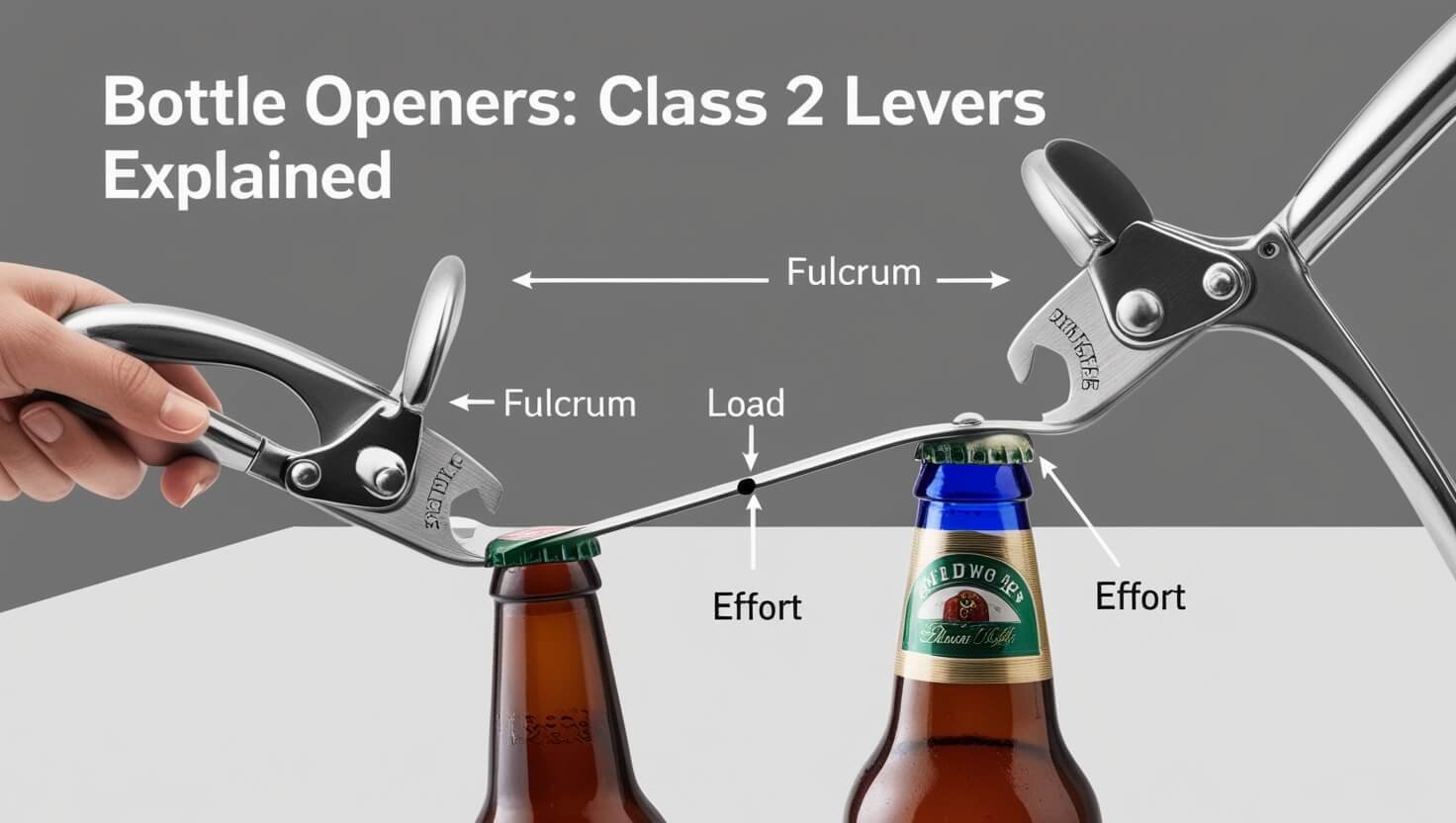

Levers come in three distinct classes, each with its own arrangement of components:

- Class 1 Levers: The fulcrum sits between the effort (where you apply force) and the load (what you’re trying to move). Think of a crowbar or scissors.

- Class 2 Levers: The load is between the effort and the fulcrum. Wheelbarrows and nutcrackers fall into this category.

- Class 3 Levers: The effort is applied between the fulcrum and the load. Your arm when you’re lifting something is a perfect example.

Each class has its advantages, and as we’ll soon see, bottle openers have a good reason for belonging to class 2.

Key Components of a Lever System

Every lever system, regardless of its class, has three essential components:

- Fulcrum: The fixed point around which the lever rotates.

- Effort: The force you apply to the lever.

- Load: The object or resistance that the lever acts upon.

Understanding how these components interact is crucial to grasping why bottle openers are so effective at their job. As we delve deeper into bottle opener mechanics, keep these components in mind – they’re the key players in the physics of popping open your favorite drink.

Bottle Openers: More Than Meets the Eye

Now that we’ve laid the groundwork, let’s zoom in on our star player – the bottle opener. This seemingly simple tool is a marvel of engineering, combining form and function in a compact package.

The Anatomy of a Bottle Opener

A typical bottle opener might look basic, but every part serves a crucial purpose:

- Handle: This is where you apply the effort. It’s usually designed for a comfortable grip.

- Tooth or Lip: The part that hooks under the bottle cap. This is where the opener makes contact with the load (the cap).

- Fulcrum: The part of the opener that rests on top of the bottle cap, acting as the pivot point.

Some bottle openers might have additional features, like a corkscrew or a can opener, but these three elements are essential for its primary function.

How Bottle Openers Work: Physics in Action

When you use a bottle opener, you’re seeing physics in action. Here’s a step-by-step breakdown of what happens:

- You hook the tooth under the bottle cap and position the fulcrum on top of the cap.

- As you apply downward force on the handle, the opener pivots around the fulcrum.

- This pivoting action creates an upward force on the tooth, which pries the cap off the bottle.

The beauty of this design is that it multiplies the force you apply, making it easy to overcome the tight seal of the bottle cap.

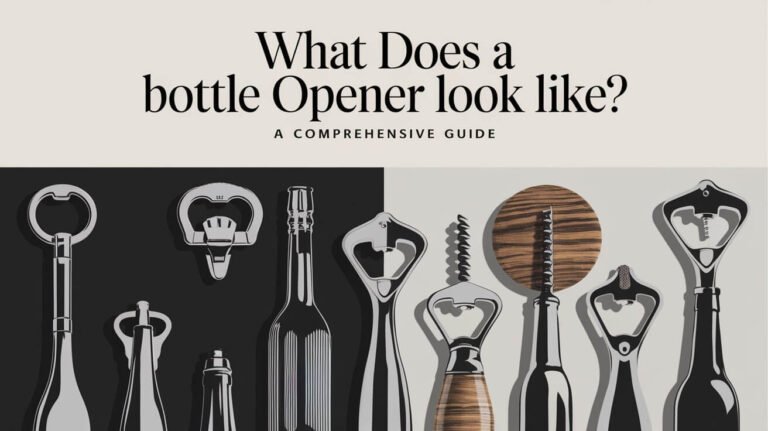

Different Types of Bottle Openers

While the basic principle remains the same, bottle openers come in various shapes and sizes:

- Bar Blade: A flat, elongated opener often used by bartenders.

- Wing Corkscrew: Combines a corkscrew with a bottle opener.

- Wall-Mounted Openers: Fixed openers often seen in bars or kitchens.

- Key Chain Openers: Compact designs for on-the-go use.

- Multi-tools: Swiss Army knives and similar tools often include a bottle opener.

Each type has its advantages, but they all operate on the same lever principle. Understanding this principle helps explain why bottle openers are so versatile and why they can be incorporated into so many different designs.

Unveiling the Class of Lever in Bottle Openers

Now that we’re familiar with the basics of levers and the anatomy of bottle openers, it’s time to answer our central question: What class lever is a bottle opener?

Drumroll, please… A bottle opener is a class 2 lever!

But why is this classification important, and what makes bottle openers fit into this category? Let’s uncap this topic and pour out the details.

Characteristics of Class 2 Levers

To understand why bottle openers are class 2 levers, we need to revisit the defining characteristics of this lever class:

- Load in the Middle: In a class 2 lever, the load (resistance) is always between the effort and the fulcrum.

- Effort at One End: The force is applied at the end of the lever, farthest from the fulcrum.

- Fulcrum at the Other End: The pivot point is at the opposite end from where the effort is applied.

Class 2 levers are known for their efficiency in lifting heavy loads with relatively less effort. This makes them ideal for tasks that require overcoming significant resistance – like prying off a tightly sealed bottle cap.

Why Bottle Openers Fit the Class 2 Lever Category

When you use a bottle opener, here’s how it aligns with the class 2 lever characteristics:

- Load (Bottle Cap): The cap you’re trying to remove is between where you’re applying force (the handle) and the fulcrum (the part resting on top of the cap).

- Effort (Your Hand): You apply force at the end of the opener, farthest from the fulcrum.

- Fulcrum (Top of the Cap): The opener pivots around the point where it contacts the top of the bottle cap.

This arrangement allows the bottle opener to multiply the force you apply, making it easy to pop off even the most stubborn caps.

Mechanical Advantage in Bottle Opener Design

The classification of bottle openers as class 2 levers is crucial to their effectiveness. This design provides a significant mechanical advantage, which is the ratio of the force produced by the machine to the force applied to it.

In a bottle opener:

- The effort arm (distance from your hand to the fulcrum) is longer than the load arm (distance from the cap to the fulcrum).

- This difference in length multiplies the force you apply, making it much easier to overcome the resistance of the bottle cap.

For example, if the effort arm is three times longer than the load arm, you’ll get a mechanical advantage of 3:1. This means that for every 1 unit of force you apply, the opener generates 3 units of force on the bottle cap.

This mechanical advantage is why you can easily open a bottle with just a small amount of effort, even though the seal on the cap might be quite strong. It’s the clever application of lever principles that makes bottle openers so efficient and user-friendly.

Understanding the class 2 lever mechanics of bottle openers not only satisfies our curiosity but also helps us appreciate the ingenuity behind this everyday tool. Next, we’ll dive deeper into the science that makes bottle openers so effective at their job.

The Science Behind Bottle Opener Efficiency

Now that we’ve established that a bottle opener is a class 2 lever, let’s delve into the scientific principles that make it so efficient. Understanding these concepts will give you a newfound appreciation for this humble tool the next time you crack open a cold one.

Force Multiplication in Bottle Openers

The key to a bottle opener’s efficiency lies in its ability to multiply force. This is achieved through the principle of mechanical advantage, which we touched on earlier. Let’s break it down further:

- Lever Arm Ratio: The longer the handle of the bottle opener compared to the distance between the fulcrum and the bottle cap, the greater the force multiplication.

- Torque Application: When you apply force to the handle, you’re creating torque around the fulcrum. The longer the handle, the more torque you can generate with the same amount of effort.

- Pressure Concentration: The tooth of the opener concentrates all this multiplied force onto a small area of the bottle cap, making it easier to break the seal.

To put this into perspective, let’s consider some numbers. If your bottle opener has a handle that’s 5 inches long, and the distance from the fulcrum to the cap is 0.5 inches, you’re getting a 10:1 mechanical advantage. This means that if you apply 5 pounds of force on the handle, the opener is applying about 50 pounds of force on the bottle cap!

The Role of Fulcrum Placement

The fulcrum’s position is crucial in a bottle opener’s design. In a class 2 lever like a bottle opener:

- Stability: The fulcrum rests on top of the bottle cap, providing a stable pivot point.

- Leverage Optimization: By placing the fulcrum close to the load (bottle cap), the opener maximizes the mechanical advantage.

- Force Direction: The fulcrum’s placement allows the opener to direct the multiplied force upward, effectively prying the cap off.

This clever placement of the fulcrum is what allows a bottle opener to work so efficiently with minimal effort from the user.

Material Considerations in Bottle Opener Design

The materials used in bottle openers also play a significant role in their efficiency:

- Rigidity: Bottle openers are typically made from rigid materials like stainless steel or hard plastics. This rigidity ensures that the force you apply is efficiently transferred to the bottle cap without the opener flexing or bending.

- Durability: The materials need to withstand repeated use and the high forces involved in opening bottles. This is why many high-quality openers are made from metals like stainless steel.

- Friction: The tooth of the opener often has a textured or slightly rough surface. This increases friction between the opener and the bottle cap, preventing slippage and ensuring a good grip.

- Weight: While not crucial, a slightly heavier opener can provide more stability and leverage, making the opening process smoother.

By considering these material properties, manufacturers can create bottle openers that are not only effective but also long-lasting and comfortable to use.

Understanding the science behind bottle opener efficiency reveals the thoughtful engineering that goes into this seemingly simple tool. From force multiplication to material selection, every aspect of a bottle opener’s design is geared towards making your beverage-opening experience as effortless as possible.

Comparing Bottle Openers to Other Lever Systems

To truly appreciate the bottle opener as a class 2 lever, it’s helpful to compare it to other lever systems. This comparison will highlight why the class 2 configuration is ideal for the task of opening bottles.

Class 1 Levers vs. Bottle Openers

Class 1 levers, where the fulcrum is between the effort and the load, are common in tools like crowbars and scissors. Let’s compare:

- Force Direction: In a class 1 lever, force is often applied downward to lift a load upward. Bottle openers, as class 2 levers, apply force downward to lift the cap upward, which is more intuitive for the task.

- Fulcrum Stress: Class 1 levers often put significant stress on the fulcrum. In bottle openers, the fulcrum (resting on the bottle cap) experiences less stress, reducing the risk of damage to the bottle.

- Size and Portability: Class 1 levers often need to be longer to provide sufficient leverage. The class 2 design of bottle openers allows for a more compact, portable tool.

While class 1 levers are excellent for many tasks, the class 2 design of bottle openers is more suited to the specific job of removing bottle caps.

Class 3 Levers vs. Bottle Openers

Class 3 levers, where the effort is between the fulcrum and the load, are found in tools like tweezers and human arms. Here’s how they compare to bottle openers:

- Force Amplification: Class 3 levers typically sacrifice force for speed or range of motion. Bottle openers, as class 2 levers, amplify force, which is crucial for removing tight caps.

- Effort Required: Class 3 levers often require more effort to move a load. Bottle openers, by contrast, reduce the effort needed, making them more user-friendly.

- Precision vs. Power: Class 3 levers excel in tasks requiring precision (like tweezers). Bottle openers prioritize power over precision, which is more appropriate for their function.

While class 3 levers have their place, the force amplification of class 2 levers makes bottle openers more efficient for their specific purpose.

Why Class 2 Is Ideal for Bottle Opening

The class 2 lever design of bottle openers offers several advantages that make it ideal for the task:

- Force Multiplication: As we’ve discussed, the class 2 design provides significant mechanical advantage, making it easy to overcome the tight seal of a bottle cap.

- Compact Design: The class 2 configuration allows for a smaller, more portable tool compared to what might be needed with a class 1 lever design.

- Intuitive Use: The downward motion required to use a bottle opener feels natural and intuitive for most users.

- Minimal Bottle Stress: The force applied is distributed in a way that minimizes the risk of breaking the bottle or damaging the cap (which could leave sharp edges).

- Versatility: The class 2 design can be easily incorporated into other tools (like corkscrews or key chains) without compromising effectiveness.

By leveraging the principles of class 2 levers, bottle openers achieve an optimal balance of force, size, and usability. This makes them not just effective, but also convenient and user-friendly.

Understanding these comparisons helps us appreciate why the class 2 lever design has become the standard for bottle openers. It’s a testament to how understanding and applying simple physics principles can lead to the creation of highly effective everyday tools.

Evolution of Bottle Opener Design

The bottle opener, while seemingly simple, has a rich history of innovation and design evolution. Understanding this history not only satisfies our curiosity but also shows how the application of lever principles has been refined over time.

Historical Perspective on Bottle Openers

The story of bottle openers is intrinsically linked to the history of bottled beverages:

- Early Days: Before dedicated openers, people used various tools or even their teeth to remove bottle caps. This was often difficult and potentially dangerous.

- Church Key: One of the earliest bottle opener designs was the “church key,” a flat metal opener that required a lifting motion. While effective, it didn’t fully leverage the class 2 lever principle.

- Crown Cork: The invention of the crown cork (the modern bottle cap) in 1892 by William Painter necessitated a specialized tool for removal, leading to the development of more efficient openers.

- Lever-Type Openers: The lever-type bottle openers we’re familiar with today began to appear in the early 20th century, applying class 2 lever principles for easier cap removal.

This evolution shows a clear trend towards designs that maximize mechanical advantage while minimizing user effort.

Innovations in Bottle Opener Technology

Over the years, bottle opener design has seen several innovations:

- Material Advancements: From simple metals to high-grade stainless steel and even durable plastics, materials have evolved to improve durability and functionality.

- Ergonomic Designs: Modern openers often feature ergonomic handles for improved grip and comfort, making the application of force easier for the user.

- Multi-functionality: Many contemporary bottle openers are part of multi-tools, combining the opener with other useful implements like corkscrews, can openers, or even USB drives.

- Automated Openers: Electric and pneumatic bottle openers have been developed for commercial settings, applying the same lever principles but with motorized force.

- Magnetic Catch: Some modern openers include a magnet to catch the cap after removal, a small but useful innovation.

These innovations demonstrate how designers continue to refine the application of class 2 lever principles in bottle openers.

Modern Variations and Multi-tool Designs

Today’s market offers a wide variety of bottle opener designs, all based on the class 2 lever principle:

- Key Chain Openers: Compact designs that can be carried anywhere, often doubling as key fobs.

- Wall-Mounted Openers: Fixed openers that leverage the stability of a wall for even easier opening. These often use a slightly modified lever design but still operate on class 2 principles.

- Credit Card Openers: Ultra-thin openers designed to fit in a wallet, proving that the class 2 lever principle can be applied even in very compact forms.

- Bartender’s Friend: A speed-opener design popular in bars, which allows for rapid opening of multiple bottles.

- Novelty Openers: Bottle openers shaped like animals, characters, or objects, showing that function can be combined with fun while still adhering to lever principles.

- Smart Openers: Some modern designs incorporate technology, like bottle openers that count the number of bottles opened or even connect to smartphones.

These variations show how the basic class 2 lever principle of the bottle opener can be adapted and applied in numerous creative ways, all while maintaining its core functionality.

DIY Bottle Openers: Leveraging Everyday Objects

While purpose-built bottle openers are the most efficient tools for the job, understanding the class 2 lever principle allows us to improvise when needed. Let’s explore how everyday objects can be used as makeshift bottle openers.

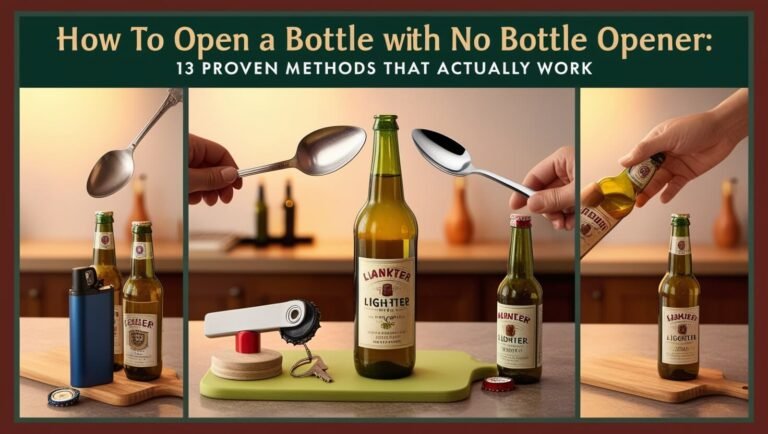

Household Items That Can Act as Bottle Openers

Many common items can serve as impromptu bottle openers:

- Edge of a Countertop: The edge can act as the fulcrum, while your hand provides the downward force.

- Spoon: The bowl of the spoon can hook under the cap, with the handle providing leverage.

- Ring: A sturdy ring can be used to catch the edge of the cap, with your finger acting as the fulcrum.

- Another Bottle: The edge of one bottle cap can be used to pry off another, though this requires careful technique.

- Flat Screwdriver: The blade can be inserted under the cap, with the shaft providing leverage.

The Physics Behind Improvised Bottle Openers

These improvised methods work because they all create a class 2 lever system:

- Fulcrum: Usually the edge of the object resting on top of the bottle cap.

- Load: The bottle cap that needs to be removed.

- Effort: The force applied by your hand, typically at a point further from the fulcrum than the load.

The effectiveness of these methods varies based on how well they can replicate the mechanical advantage of a proper bottle opener. Objects with longer “handles” or that allow for a better grip tend to work better as they provide more leverage.

Safety Considerations When Using Alternative Methods

While these improvised methods can be useful in a pinch, they come with some risks:

- Injury Risk: Improper use of sharp or hard objects can lead to cuts or other injuries.

- Damage to Objects: Using items not designed for opening bottles may damage them or the bottle itself.

- Broken Glass: There’s a higher risk of breaking the bottle when using improvised methods.

- Reduced Efficiency: These methods often require more force and skill than a proper opener.

It’s always safer and more efficient to use a tool designed for the job. However, understanding the lever principles behind bottle openers allows for clever improvisation when necessary.

Bottle Openers in Different Industries

While we often think of bottle openers in a personal or hospitality context, their application of class 2 lever principles extends into various industries.

Commercial Applications of Bottle Opener Mechanisms

The bottle opener mechanism finds use in several commercial settings:

- Beverage Industry: High-speed, automated bottle openers in bottling plants use the same lever principle but on a larger scale.

- Packaging Industry: Some packaging removal tools use similar lever mechanisms to break seals or remove caps.

- Automotive Industry: Certain specialized tools for removing car parts operate on similar lever principles.

Bottle Openers in the Food and Beverage Industry

In the food and beverage industry, bottle openers play a crucial role:

- Bars and Restaurants: Speed openers allow bartenders to quickly serve multiple customers.

- Breweries: Specialized openers are often used in the bottling and quality control processes.

- Event Catering: Portable, efficient openers are essential for serving bottled drinks at large events.

Specialized Bottle Openers for Unique Bottle Types

Not all bottles are created equal, leading to specialized opener designs:

- Swing-Top Bottle Openers: For bottles with swing-top or bail closures.

- Cork Removers: While not technically for “caps,” these still operate on lever principles.

- Crown Cap Removers: Designed specifically for traditional crown caps.

- Plastic Cap Openers: For twist-off caps that might be too tight for hand-opening.

These specialized tools show how the class 2 lever principle can be adapted to various specific needs while maintaining its core efficiency.

The Future of Bottle Openers

As we look to the future, it’s exciting to consider how this simple yet effective tool might evolve. While the basic class 2 lever principle is likely to remain at the core of bottle opener design, we can expect to see new innovations and adaptations.

Emerging Technologies in Bottle Opening

Several technological advancements are being applied to bottle opening:

- Smart Openers: Bottle openers with built-in counters or even Bluetooth connectivity to track consumption or integrate with smart home systems.

- Automated Home Systems: Voice-activated or app-controlled bottle opening machines for home bars.

- Enhanced Materials: Development of new, more durable and efficient materials for opener construction.

- 3D Printed Customization: The ability to design and print custom bottle openers tailored to individual preferences or needs.

Sustainability Trends in Bottle Opener Design

As environmental concerns grow, we’re seeing trends towards more sustainable bottle opener designs:

- Recycled Materials: Openers made from recycled metals or plastics.

- Biodegradable Options: For disposable openers, materials that break down more easily in the environment.

- Multi-use Designs: Openers integrated into other tools to reduce overall resource use.

- Longer-lasting Builds: Focus on durability to reduce the need for frequent replacements.

Predictions for Next-Generation Bottle Openers

Looking ahead, we might see bottle openers that:

- Adapt to Different Cap Types: Universal openers that can handle various bottle sealing mechanisms.

- Incorporate Health Monitoring: Openers that can detect if a drink has been tampered with or if it’s at the optimal temperature.

- Energy Harvesting: Openers that capture the energy used in opening bottles to power small electronics or charge batteries.

- Augmented Reality Integration: Openers that can scan bottles and provide information about the beverage through a smartphone app.

While these advancements may add new features, the core class 2 lever principle is likely to remain the fundamental mechanism for efficient bottle opening.

Ending Thoughts

Bottle openers show how simple machines work in real life. They use the power of levers to make opening bottles easy. Over time, people have made many types of openers for different needs. From basic tools to fancy gadgets, all openers use the same idea of force and leverage.

Next time you open a bottle, think about the science behind it. This small tool shows how clever design can solve everyday problems. The bottle opener proves that understanding basic science can lead to useful inventions.