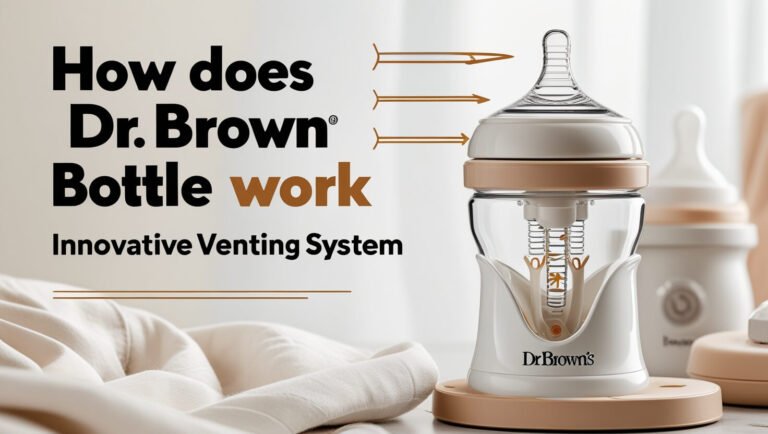

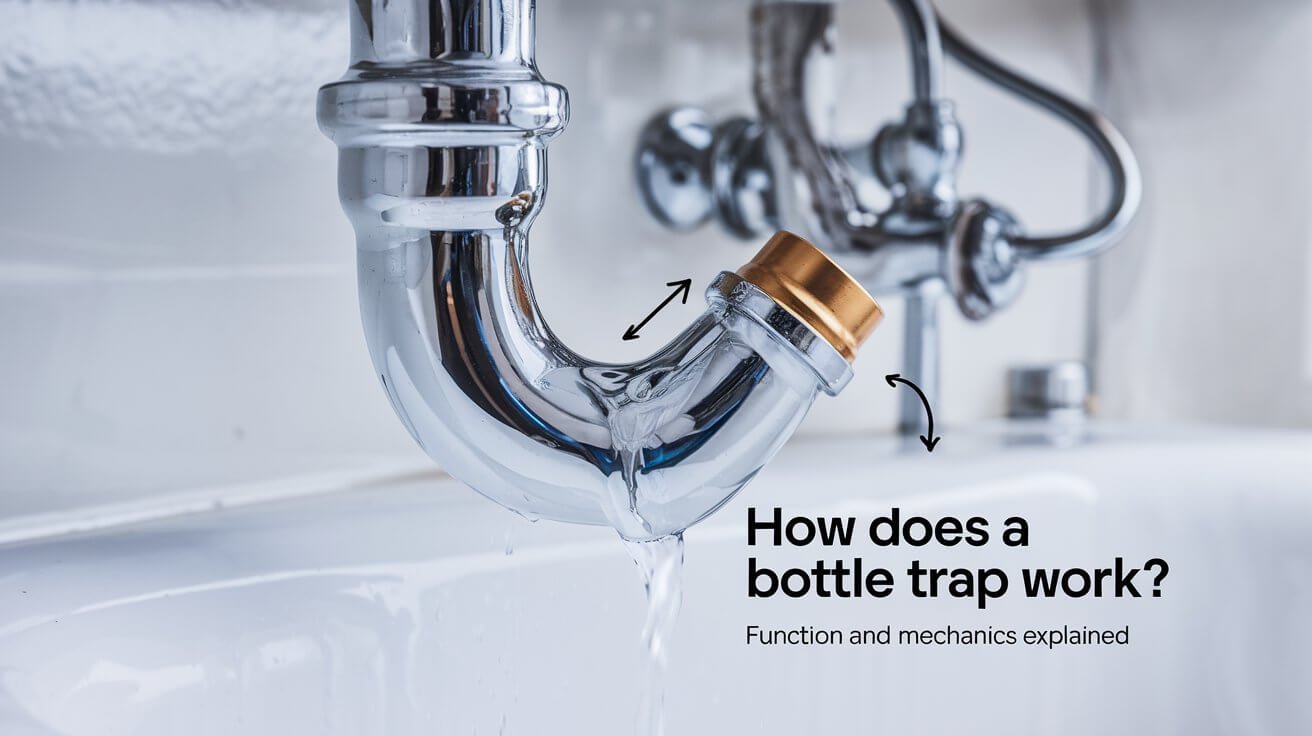

How Does a Bottle Trap Work: Function and Mechanics Explained

A bottle trap is key in your plumbing system, trapping debris and preventing blockages. But have you ever thought about how it keeps sewer gases out of your home? The bottle trap mechanism creates a water seal, stopping these gases. This keeps the water level constant in the bend, acting as a barrier.

This raises a question: what makes the bottle trap so effective in preventing blockages and keeping the air fresh? The bottle trap function is vital in keeping sewage gases out of living spaces. It helps prevent blockages in waste pipes, ensuring smooth drainage even with heavy use.

So, how does a bottle trap work to achieve this, and what are the benefits of using one? The answer lies in the bottle trap mechanism. This article will dive into the bottle trap function and its importance in modern plumbing.

Basic Principles Behind Bottle Trap Design

The bottle trap design works on three main principles. It uses a water seal, relies on gravity, and has anti-siphon properties. This makes it a great choice for plumbing in kitchens and bathrooms. The bottle trap operation keeps bad smells and gases out, while gravity helps it drain wastewater.

The bottle trap plumbing system keeps sewer gases away from your space. It also stops water from being sucked out of the sink. This ensures a steady water seal. The design and how it works are key to a plumbing system that works well and doesn’t smell bad.

Some key features of bottle trap design include:

- Water seal function to prevent foul odors and gases

- Gravity-based operation for efficient wastewater drainage

- Anti-siphon properties to prevent water siphoning from the sink

The bottle trap design is vital for plumbing systems. It keeps your environment healthy and safe. Knowing how bottle trap design, bottle trap operation, and bottle trap plumbing work helps us see why they need regular care and proper setup.

| Feature | Description |

|---|---|

| Water Seal | Prevents foul odors and gases from returning to the drain |

| Gravity-Based Operation | Allows the trap to drain wastewater from the sink |

| Anti-Siphon Properties | Prevents the trap from siphoning water from the sink |

Core Components of a Bottle Trap

The bottle trap has key parts that make it work. The main part is the trap itself. It keeps water to block sewer gases from getting in.

The trap works by using gravity and water to seal the air. It holds water to keep sewer gas out. The waste pipe takes wastewater away, and the overflow pipe stops the sink from overflowing.

Some important features of bottle traps are:

- Available in 32mm and 40mm sizes

- Designed to catch small and heavy items dropped down the sink

- Help to limit the size of objects entering the plumbing system

In the United States, these traps are called P-traps. They have a 90-degree fitting on the outlet side of a U-bend. Thomas Crapper introduced the U-shaped trap in 1880, known as the U-bend after that. The bottle trap’s parts and function make plumbing systems reliable and efficient.

| Trap Type | Size | Features |

|---|---|---|

| Bottle Trap | 32mm, 40mm | Water seal, gravity-based operation |

| S-bend Trap | 32mm, 40mm | U-shaped design, 90-degree fitting |

| P-trap | Varying sizes | 90-degree fitting, water seal |

Knowing about bottle trap components and its function helps everyone. Homeowners and plumbers can see why it’s vital for a good plumbing system.

Physical Structure and Materials

The design and function of a bottle trap depend on its physical structure and materials. Bottle traps can be made from bottle trap materials like metal and plastic. Each material has its own benefits and drawbacks. The choice depends on the trap’s purpose, how long it will last, and its resistance to corrosion.

Choosing the right bottle trap size is key for proper function. The trap’s size must match the sink and waste pipe. A trap that’s too small might not handle water flow well. On the other hand, a trap that’s too large is unnecessary and costly.

Connection Points

The bottle trap connection points are vital for preventing leaks. They must be secure and watertight. The connections should handle water pressure and flow well. They should also be easy to install and maintain.

- Secure and watertight connections to prevent leaks

- Easy to install and maintain

- Able to withstand water pressure and flow rate

In summary, the physical structure and materials of a bottle trap are key. By picking the right bottle trap materials, bottle trap size, and bottle trap connection points, you can have a working and efficient plumbing system.

| Material | Advantages | Disadvantages |

|---|---|---|

| Metal | Durable, resistant to corrosion | Expensive, heavy |

| Plastic | Lightweight, inexpensive | Less durable, prone to cracking |

How Does a Bottle Trap Work in Your Plumbing System

A bottle trap is key in plumbing, and its bottle trap operation stops blockages and keeps smells away. It creates a water seal that blocks sewer gases from rising into your home. This keeps your bathroom or kitchen smelling fresh.

The bottle trap plumbing system keeps sewage gases out of your living areas. It’s a must-have for every sink or basin. Bottle traps neutralize odors and stop harmful germs, making your home healthier. Some main benefits include:

- Preventing blockages by catching waste, ensuring smooth drainage

- Reducing sewerage gas back-ups, meeting health standards

- Improving pipe and drain performance

For the bottle trap function, regular cleaning is a must. How often depends on how much you use it. For often-used sinks, clean twice a month; for less used ones, once a month. Knowing how a bottle trap works helps you see its role in keeping your home safe and healthy.

Chemical Resistance and Durability Features

When picking bottle trap materials, durability and chemical resistance are key. The trap’s material must handle the chemicals flowing through it well. The quality of materials used affects how long the trap lasts and how well it resists corrosion and wear.

Chemical resistance is also vital. The trap must handle various chemicals and substances without damage. Some materials, like brass and stainless steel, are known for their durability and resistance to corrosion. This makes them popular for bottle traps.

Material Compatibility

The material of a bottle trap is critical. It must handle the chemicals and substances flowing through it. Metal and plastic are common materials, each with its own pros and cons. Metal traps are often more durable and resistant to chemicals, while plastic traps are cheaper and easier to install.

Lifespan Expectations

The lifespan of a bottle trap depends on several factors. These include the material and design. A well-made trap with quality materials can last for years. On the other hand, a poorly made trap may need frequent replacement. Regular maintenance and cleaning can also help extend its life.

| Material | Chemical Resistance | Durability |

|---|---|---|

| Brass | High | High |

| Stainless Steel | High | High |

| Plastic | Medium | Medium |

Common Applications in Modern Plumbing

Bottle traps are key in modern plumbing, found in bathrooms and kitchens. They fit well in small spaces. The bottle trap function stops sewer gases from getting in and keeps water from siphoning out.

In bottle trap applications, they pair well with sinks and other fixtures. The bottle trap plumbing system moves lots of water efficiently. It’s great for homes and businesses because it’s easy to install and maintain, and looks good too.

Here are some key features and benefits of bottle traps:

- Easy to clean and maintain

- Visually appealing designs

- Compact and space-efficient

- Provides a water seal to prevent siphoning

- Essential component of a plumbing system

Choosing the right bottle trap depends on the plumbing system, water use, and look you want. Knowing about bottle trap applications and bottle trap plumbing helps make the best choice.

| Feature | Benefit |

|---|---|

| Compact design | Suitable for smaller bathrooms or installations |

| Easy to clean | Low maintenance requirements |

| Visually appealing designs | Enhances the aesthetic appeal of the plumbing system |

Installation Requirements and Specifications

When installing a bottle trap, it’s important to follow the requirements and specifications carefully. You need to make sure the trap is in the right spot and connected correctly. This prevents leaks and keeps it working well. You’ll need tools like a pipe wrench, pliers, and a screwdriver for the job.

Choosing the right size and type of trap is key. The material and shape of the trap also matter a lot. For example, stainless-steel traps are great because they don’t rust and last a long time. They’re often chosen for their durability and look.

Key Considerations for Bottle Trap Installation

- Proper positioning to ensure the trap is level and secure

- Watertight and secure connection methods to prevent leaks

- Selection of the right bottle trap specifications, including size and material

To have a successful installation, follow the bottle trap requirements and specifications. It’s also important to keep the trap clean and check it regularly. This helps avoid clogs and keeps the trap working well.

| Trap Type | Material | Size |

|---|---|---|

| Stainless-Steel Bottle Trap | Stainless Steel | 32 mm with 300 mm & 175 mm |

| Brass Bottle Trap | Brass | 32 mm with 250 mm & 190 mm |

Maintenance and Cleaning Protocols

Regular bottle trap maintenance is key to keeping the trap working right. It helps avoid blockages. You should check the water seal and clean the trap to keep it effective and clear.

Bottle trap cleaning is important to stop debris and odors from building up. Following cleaning protocols is a must.

To keep a bottle trap in good shape, regularly check for wear and damage. Look for any blockages or harm. Also, make sure to follow bottle trap protocols for proper function. This includes checking the water seal and ensuring good ventilation.

Here are some tips for maintaining a bottle trap:

- Check the trap regularly for signs of wear and tear

- Follow bottle trap cleaning protocols to prevent the buildup of debris and odors

- Ensure the trap is properly vented to prevent siphoning

- Check the water seal to ensure it’s functioning correctly

By following these tips and bottle trap maintenance protocols, you can keep your trap working well. This prevents blockages and odors. Regular bottle trap cleaning and upkeep also extend its life and save on repairs.

| Maintenance Task | Frequency |

|---|---|

| Check trap for signs of wear and tear | Monthly |

| Follow bottle trap cleaning protocols | Every 1-3 months |

| Check water seal | Every 6 months |

Signs of Malfunction and Damage

A bottle trap malfunction can show itself in many ways, like water leaks and poor drainage. It’s important to check the trap often to catch problems early. Bottle trap damage can cause bigger issues, like water damage or sewage backups, if not fixed.

Some common signs of a bottle trap malfunction include:

- Water spots or warping of the surrounding material

- Slow draining or gurgling sounds

- Unpleasant odors

It’s key to spot these bottle trap signs and act fast to avoid more damage. Keeping the trap clean and checking for blockages can help prevent problems. This ensures the trap works right.

A well-kept bottle trap helps avoid bottle trap damage and keeps drainage smooth. Knowing the signs of malfunction and acting early can save you from expensive fixes. It keeps your plumbing system running well.

| Signs of Malfunction | Description |

|---|---|

| Water Leakage | Water spots or warping of the surrounding material |

| Drainage Issues | Slow draining or gurgling sounds |

| Unpleasant Odors | Unpleasant smells coming from the drain |

Building Code Requirements and Standards

Installing a bottle trap must follow building codes and standards. These rules change based on where you are and the type of installation. It’s key to know the bottle trap codes, standards, and requirements for proper and safe function.

In homes, the size of fixture traps varies. They range from 1 1/4 inches for water stations to 3 inches for certain sinks. Some traps, like bell traps, are not allowed because they can cause drainage and ventilation problems.

Residential Specifications

In homes, each trap must have a liquid seal of 2 to 4 inches. Cleanouts on hidden pipes must reach the wall or floor. Also, cleanouts on big pipes should not be more than 100 feet apart.

Commercial Guidelines

In businesses, the rules for bottle traps are stricter. Traps must be level and protected from freezing. In some cases, inspectors can approve running traps. Cleanouts on underground pipes need to be accessible.

| Trap Type | Minimum Size | Maximum Size |

|---|---|---|

| Drinking Water Station | 1 1/4 inches | 2 inches |

| Flushing Rim Type Sink | 2 inches | 3 inches |

By adhering to these bottle trap codes and standards, you can have a safe and working plumbing system. Always check with local authorities for specific rules in your area.

Performance Comparison with Other Trap Types

When we talk about bottle trap comparison, we look at performance, function, and how long they last. Bottle traps are often compared to P-traps and S-traps. Each has its own strengths and weaknesses, depending on the job and needs.

There are different bottle trap types like PVC, brass, and stainless steel. PVC traps are light and easy to put in. Brass and stainless steel traps last longer. Prices vary based on material, size, and brand, with Essco having a wide range at good prices.

Using bottle traps has many benefits:

- They stop sewage gas back-ups and leaks.

- They cut down sewerage gas back-ups in kitchen and bathroom pipes.

- They stop wastewater from flowing back.

- They make pipes work better.

Using bottle traps under sinks helps avoid clogs and keeps things clean. How often to clean a bottle trap depends on use. For often-used sinks, clean twice a month. For less-used ones, clean once a month. Choosing the right bottle trap type and keeping it clean ensures your plumbing works well.

Final Thoughts

The bottle trap is key in any modern plumbing system. It’s small, keeps water sealed, and stops siphoning. This makes it perfect for tight spaces in bathrooms and kitchens.

Keeping it clean is important. It helps prevent bad smells, clogs, and keeps your plumbing healthy. This is vital for your home’s hygiene.

Knowing about bottle traps is important for everyone. Homeowners, plumbers, and contractors need to understand its role. Following local codes and standards ensures your plumbing is safe and works well.

The bottle trap is the last piece in your plumbing setup. It improves both function and looks of your space. It’s a small but essential part of your plumbing system.