What Are Bottle Caps Made Of – Materials Guide

Ever think about the caps on your favorite drinks? They’re not just for sealing. They’re key to the packaging, keeping your drinks safe and making them fun to use. Next time you open a bottle, look closely at the materials and tech that make these caps special.

History of Bottle Cap Manufacturing

The story of bottle cap making starts in the late 1800s. William Painter, an American inventor, created the first bottle cap in 1892. His design had 24 teeth and a cork seal with paper backing, called the “crown cork.”

This new way to close bottles changed the industry. It made it easier to keep glass bottles sealed and fresh.

As time went on, bottle cap designs got better. In the 1960s, a twist-off crown cap was introduced in Germany. It made opening bottles easier and more convenient. Today, crown caps have 21 teeth and often use plastic liners instead of cork.

Major Manufacturing Milestones

The bottle cap industry has seen big changes and improvements. Some key moments include:

- 1892: William Painter patents the first bottle cap, the “crown cork,” in Baltimore, Maryland.

- 1960s: The twist-off crown cap is introduced in Germany, becoming a popular design choice in the United States, Canada, and Australia.

- 2021: The European Union directive on “tethered caps” requires that screw caps of PET beverage bottles under 3 liters be affixed to the bottles, reducing waste and improving recycling.

These changes in bottle cap technology have made things better for users. They have also helped the bottle cap industry grow and improve.

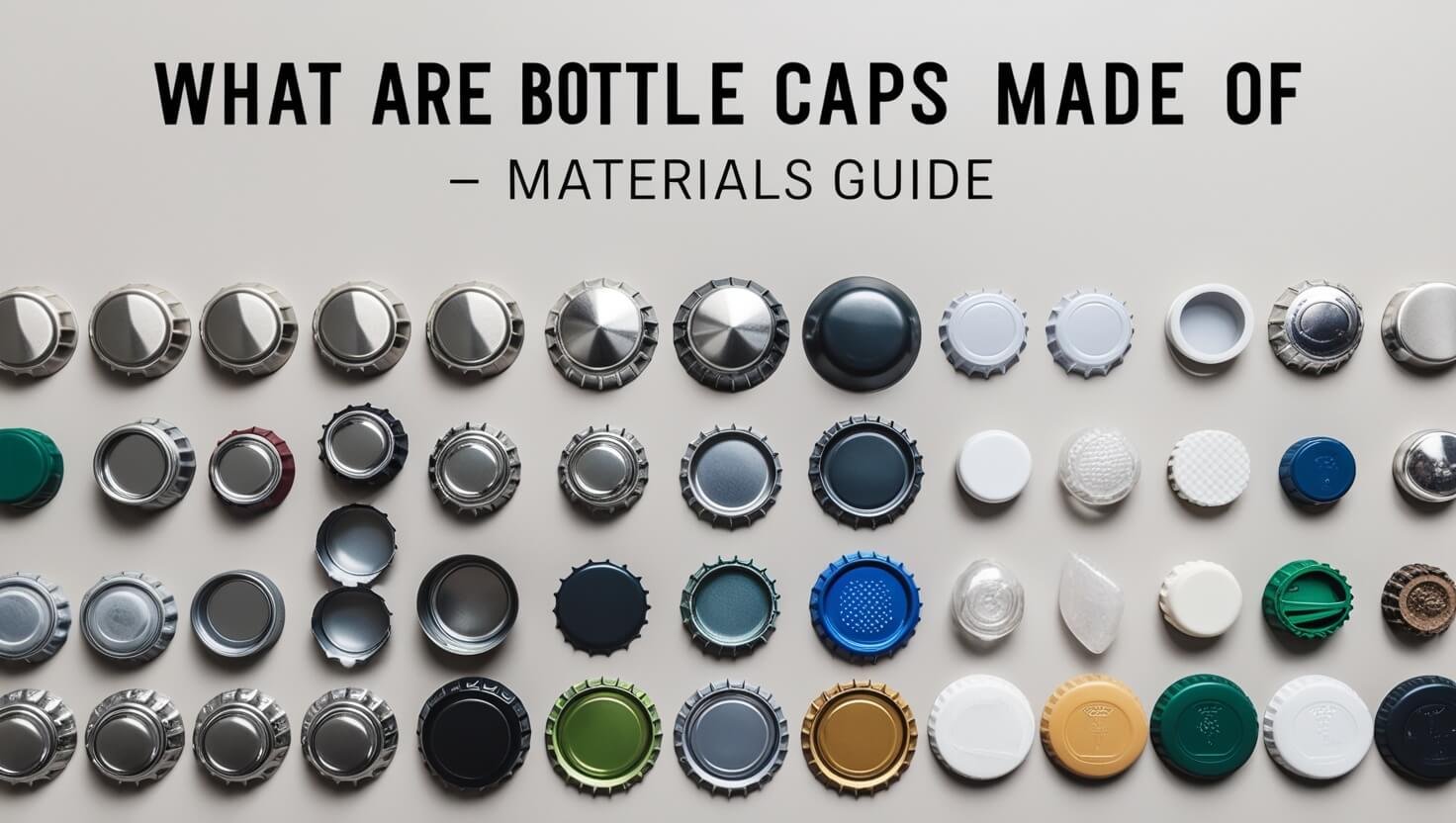

Types of Modern Bottle Caps

The world of bottle caps has changed a lot. Now, we have many modern designs and materials. This is to meet the changing tastes of people.

The plastic screw cap is very common today. It’s made from polyethylene (PE) or polypropylene (PP). These caps are great for plastic bottles because they’re easy to use and can be opened many times.

The metal crown cork has been around for over a century. It’s made of metal, sometimes with a plastic coating. These caps are often used on glass bottles for drinks like beer and soda.

- Flip-top or swing-top closures use a plastic or ceramic stopper held by wires. They’re easy to open with one hand.

- Sports caps are perfect for water bottles. They let you drink without taking off the cap, great for those who are always on the move.

- Cork stoppers offer a classic look. They work by compressing into the bottle neck, keeping things fresh.

Modern bottle caps go beyond the usual screw-on and cork types. We now have trigger heads, spray caps, and pump caps. These are for special products and uses.

Bottle caps are key to keeping products fresh and safe. As packaging tech gets better, we’ll see even more types of bottle caps. This will meet the changing needs and tastes of people.

What Are Bottle Caps Made Of

Bottle caps are small but key parts that keep our drinks safe. They are made from different materials. Knowing what these materials are helps both buyers and makers.

Primary Materials Overview

Bottle caps fall into two main groups: metal and plastic. Metal caps are usually steel or aluminum, with extra coatings. Plastic caps are made from PET, Polypropylene, and other plastics.

Metal Components and Alloys

Steel and aluminum are the top metals for bottle caps. They are picked for being strong and lasting. Metal caps also get special coatings to fight off rust and look good.

Plastic Materials and Polymers

Plastic caps are lighter and more flexible than metal ones. PET and Polypropylene are common plastics. They are safe, keep things in, and resist chemicals well.

| Material | Key Properties | Common Applications |

|---|---|---|

| Steel | Durable, strong, corrosion-resistant | Metal bottle caps |

| Aluminum | Lightweight, malleable, corrosion-resistant | Metal bottle caps |

| Polyethylene Terephthalate (PET) | Non-toxic, strong, recyclable | Plastic bottle caps, beverage containers |

| Polypropylene | Heat-resistant, chemical-resistant, recyclable | Plastic bottle caps, food packaging |

The choice of material for bottle caps depends on the bottle, what’s inside, and how it’s used. This ensures a tight and lasting seal for many products.

Metal Bottle Cap Materials

Metal bottle caps are key in the beverage world, made mostly of steel or aluminum. Steel caps have special coatings like chrome or tin to fight corrosion. They also handle heat and impacts well. Some caps add plastisol, pulp/aluminum foil, or solid polyethylene for better sealing.

Steel is the top pick for beer bottle tops, like those on Australian stubbies. These caps are magnetic, showing they’re made from thin steel. Even though they’re cheap, they can rust because they’re not high-quality stainless steel.

Aluminum is used for caps too, but less often than steel. Aluminum caps don’t work well for DIY projects because they oxidize fast. For better results, use aluminum from car parts, like engine bits.

Every cap, no matter the metal, starts as a sheet. They have a plastic bottom to stop rust. The choice of metal and coating depends on the product and packaging needs.

Plastic Bottle Cap Composition

Modern bottle caps often use plastic, which is better than metal in many ways. The top plastics for caps are Polyethylene Terephthalate (PET), Polypropylene (PP), and High-Density Polyethylene (HDPE).

Polyethylene Terephthalate (PET)

PET caps are strong, last long, and can be recycled. They’re great for drinks like soda, water, and oil. This is because PET is safe, light, and doesn’t react with chemicals.

Polypropylene Applications

Polypropylene is popular for caps on bottles that can handle heat. It’s good because it doesn’t react with chemicals and keeps things in. It’s also strong and works well with fast capping machines.

High-Density Polyethylene Usage

HDPE is used a lot for bottle caps too. It’s stable, doesn’t react with acids, and seals well. This makes it perfect for bottles that hold chemicals or health products.

| Plastic Material | Key Properties | Common Applications |

|---|---|---|

| Polyethylene Terephthalate (PET) | Strength, Durability, Recyclability | Carbonated Beverages, Mineral Water, Edible Oils |

| Polypropylene (PP) | Chemical Resistance, Barrier Properties, Rigidity | Heat-Resistant Beverage Bottles |

| High-Density Polyethylene (HDPE) | Stability, Acid Resistance, Sealing Performance | Chemical Packaging, Health Product Bottles |

Bottle Cap Liners and Sealing Materials

Bottle cap liners are key to keeping contents safe and sealed. They come in many types, each with its own benefits. This makes them perfect for different products and uses.

3-ply foam is a common choice for household items, food, liquor, cosmetics, and medicines. Polyethylene foam liners are also popular. They work well for household goods, general use, water-based items, and for sealing with pressure.

Pressure-sensitive foam liners are great for thick liquids, dry goods, and powders. They last up to 6 months. Induction liners are used for food, liquor, liquids, and medicines. They make a seal that shows if someone has opened it.

| Liner Type | Recommended Applications |

|---|---|

| 3-Ply Foam (F217) | Household products, food & liquor, cosmetics, and pharmaceuticals |

| Polyethylene Foam | Household products, general-purpose liners, water-based products, and pressure-sensitive applications |

| Pressure Sensitive (PS 22) | Thick liquids, dry products, and powders with a recommended shelf life of 6 months |

| Induction | Food & liquor, liquid products, and pharmaceuticals (provides a tamper-evident seal) |

There are also poly vinyl, polyseal, Teflon PTFE, foil, and plastisol liners. Each has special benefits like resisting chemicals, protecting taste and smell, or sealing tightly.

Gaskets, made of rubber or plastic, are also important. They help make a tight seal. Some liners even have oxygen-absorbing substances to keep products fresh.

Manufacturing Processes and Techniques

Modern bottle caps are made using advanced methods. These include injection molding for plastic and precision engineering for metal. Each step is key to ensuring quality and performance.

Injection Molding Process

Most plastic bottle caps are made by injection molding. This process heats and mixes plastic, then injects it into a mold. It cools and hardens into the cap shape. This method is efficient and precise, making many caps at once.

Metal Cap Production Methods

Metal caps are made with special machines. These machines create the cap’s curved edges and add coatings or sealants. Stainless steel molds are used to make multiple caps at once, boosting efficiency.

Quality Control Standards

Keeping quality high is critical in making bottle caps. Automated systems and quality checks are used throughout. These ensure caps meet standards and regulations. Checks include size, material, and visual inspections.

| Quality Control Metric | Acceptable Range |

|---|---|

| Dimensional Accuracy | +/- 0.1 mm |

| Material Composition | 100% compliance with specified formulations |

| Defect Rate | Less than 0.01% per production run |

Following strict quality standards, manufacturers ensure their caps perform well. This gives consumers a great experience every time.

Safety Standards and Regulations

Keeping food safe is very important, and bottle caps play a big role. They must follow many safety rules to protect us and keep food quality high.

In the United States, the FDA watches over food contact materials. They make sure bottle caps are safe for food and drinks. This is all under Title 21 of the Code of Federal Regulations.

The European Union also has rules for plastic in contact with food. Countries like Canada, Australia, and New Zealand have their own rules too. These rules help keep food safe and products reliable.

Following bottle cap regulations, food safety standards, and packaging regulations is key. It shows companies care about our health. It also keeps customers trusting them.

| Region | Regulations | Key Requirements |

|---|---|---|

| United States | FDA Title 21 Code of Federal Regulations | Specific requirements for food contact materials, including bottle caps |

| European Union | EU Commission Regulation (EU) No.10/2011 | Establishes requirements for plastic materials and articles intended to come into contact with food |

| Canada | Food and Drug Regulations, Division 23 | Regulates packaging materials used in the sale of foods |

| Australia and New Zealand | Food Standards Code | Requires manufacturers to ensure food in contact with packaging is safe |

By following these rules, bottle cap makers can make safe products. This gives us a reliable way to package our food and drinks.

Final Verdict

The bottle cap industry is changing, focusing on being green and new. More caps are made from recycled materials. They also aim to be better for the planet and easier to use.

Now, more bottle caps are made from recycled plastics. Companies are using lighter materials and greener ways to make them. This helps fight the big problem of plastic waste, harming marine life.

The industry is also getting better at making caps that are safe and easy to use. They’ve added features like tamper-evident closures and easy-open designs. These changes show the industry’s effort to meet new needs and keep improving.

Simple Questions:

What are bottle caps mainly made of?

Bottle caps are mostly made of plastics or metals. Plastic caps use materials like PET, Polypropylene, and HDPE. Metal caps are usually steel or aluminum, sometimes with a protective coating.

What are the different types of modern bottle caps?

Today, we have plastic screw caps, metal crown corks, and flip-top closures. Plastic caps are on plastic bottles, while metal caps are on glass. Some metal caps have a plastic coating. Flip-top caps use a plastic or ceramic stopper held by wires.

How are plastic bottle caps typically produced?

Plastic bottle caps are made by injection molding. This method heats and mixes plastic, then injects it into a mold. It cools and hardens there.

What are some common materials used in metal bottle caps?

Metal caps are made of steel or aluminum. Steel caps have coatings like chrome or tin to prevent corrosion. These materials can handle a wide range of temperatures and are impact-resistant. Some caps also have plastisol or pulp/aluminum foil for better sealing.

What are some common materials used in plastic bottle caps?

PET is a key material for plastic caps, known for its strength and recyclability. Polypropylene is used for its chemical resistance. HDPE is chosen for its stability and sealing ability, often in chemical bottles.

What are bottle cap liners and what do they do?

Bottle cap liners improve sealing and protect what’s inside. They include 3-ply foam and polyethylene foam. Each type offers benefits like chemical resistance and taste protection. Gaskets, made of rubber or plastic, ensure a tight seal.

What safety standards and regulations apply to bottle caps?

Bottle caps must meet many safety standards. In the U.S., the FDA oversees food contact materials. The EU has rules for plastic in food contact. Countries like Canada and Australia also have their own standards for food packaging, ensuring safety and quality.